1. Product Feature And Application of SMTYT6030A Integrated Inductor

Features:

1. Small volume (maximum size7.5*6.8*3.0 mm) and large current (range up to 60A), maintaining excellent temperature-rise current and saturation current characteristics at high frequency and high temperature.

2. The inductance ranges from 0.10uH to 33.00uH.

3. Magnetic shielding structure, anti-electromagnetic interference (EMI) performance is strong.

4. Low loss alloy powder die casting, low impedance, low parasitic capacitanceg.

5. High efficiency, wide application frequency and wide application range.

Applications:

1. Low profile ,high current power supplies.

2. DC/DC converters.

3. Battery powered devices.

4. PDA/notebook/desktop/server applications.

Part Numbering

|

SMTYT |

6030 |

A |

2R2 |

M |

|

(1) |

(2) |

(3) |

(4) |

(5) |

|

(1) Series: SMTYT meter integrated inductance |

||||

|

(2)Dimension: 60=6.0 Series 30=Product height 3.0mm |

||||

|

(3) Materials Type: A=alloy powder C=carbonyl powder |

||||

|

(4)Inductance: 2R2=2.2uH 100=10uH 101=100uH |

||||

|

(5)Inductance Tolerance: J=±5% K=±10% L=±15% M=±20% |

||||

2. Product Introduction of SMTYT6030A Integrated Inductor

SMTYT6030A integrated inductor introduction: SMTYT6030A integrated inductor has high stability and high reliability. The stability and reliability of SMTYT6030A integrated inductors are relatively high. Our products have relatively high stability and quality as well as comply with EU standards. We have a broad market in China and overseas. Our products can be customized according to customer needs.

3. Product Parameter (Specification) of SMTYT6030A Integrated Inductor

|

MOLDING SMD POWER INDUCTOR SMTYT6030A SERIES |

|||||||||||

|

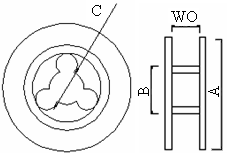

Dimensions and Recommend PC Board Pattern (unit: mm ). |

|||||||||||

|

|

|||||||||||

|

ITEM |

A |

B |

C |

D |

E |

||||||

|

SPEC |

7.0±0.5 |

6.6±0.2 |

3.3 MAX |

3.0±0.3 |

1.6±0.3 |

||||||

|

Material List:

|

|||||||||||

|

No. |

ITEM |

Materials |

|||||||||

|

a |

Core |

Metal alloy |

|||||||||

|

b |

Wire |

Polyester Wire or equivalen |

|||||||||

|

c |

Terminal |

Copper+Nickel+Tin |

|||||||||

|

d |

Ink |

KGK-JET LTH20-Black or equivalen |

|||||||||

Storage conditions/Matters need attention:

1. Storage temperature and humidity conditions:

a. Product packing with Carrier tape: -10℃~+40℃and less than 60% RH

b. Product alone: -20℃~+60℃and less than 60% RH

2. Products should be used within 6 months.(Note that the product should be used as soon as possible once it is folded)

3. The packaging material should be kept where no chlorine or sulfur exists in the air.

4. Do not touch the electrodes (soldering terminals) with fingers as this may lead to deterioration of solder ability.

5. The use of tweezers or vacuum pick-ups is strongly recommended for individual components.Bulk handling should ensure that abrasion and mechanical shock are minimized.

Electrical Characteristics:

|

Part number |

Inductance (uH) |

Rdc (mΩ) |

Heat Rating Current DC Amps. Idc ( A ) |

Saturation Current DC Amps. Isat ( A ) |

||

|

100KHz/0.25V |

Typical |

Max |

Max |

Max |

||

|

SMTYT6030A-R10M |

0.10±20% |

1.50 |

1.70 |

32.50 |

60.00 |

|

|

SMTYT6030A-R15M |

0.15±20% |

1.90 |

2.50 |

30.00 |

40.00 |

|

|

SMTYT6030A-R22M |

0.22±20% |

2.50 |

3.00 |

21.00 |

34.00 |

|

|

SMTYT6030A-R33M |

0.33±20% |

3.00 |

3.50 |

21.00 |

25.00 |

|

|

SMTYT6030A-R47M |

0.47±20% |

3.50 |

4.10 |

18.00 |

20.00 |

|

|

SMTYT6030A-R56M |

0.56±20% |

4.25 |

4.90 |

15.00 |

18.00 |

|

|

SMTYT6030A-R68M |

0.68±20% |

5.00 |

5.70 |

14.00 |

17.00 |

|

|

SMTYT6030A-R82M |

0.82±20% |

6.00 |

6.90 |

12.00 |

16.00 |

|

|

SMTYT6030A-1R0M |

1.00±20% |

7.00 |

7.50 |

11.00 |

15.00 |

|

|

SMTYT6030A-1R2M |

1.20±20% |

8.00 |

10.50 |

10.00 |

14.00 |

|

|

SMTYT6030A-1R5M |

1.50±20% |

10.60 |

12.10 |

9.00 |

14.00 |

|

|

SMTYT6030A-2R2M |

2.20±20% |

15.50 |

17.50 |

7.00 |

10.00 |

|

|

SMTYT6030A-3R3M |

3.30±20% |

23.00 |

26.00 |

6.00 |

9.50 |

|

|

SMTYT6030A-4R7M |

4.70±20% |

34.50 |

38.00 |

5.50 |

6.50 |

|

|

SMTYT6030A-5R6M |

5.60±20% |

36.00 |

42.00 |

5.00 |

6.25 |

|

|

SMTYT6030A-6R8M |

6.80±20% |

43.00 |

50.00 |

5.00 |

6.00 |

|

|

SMTYT6030A-8R2M |

8.20±20% |

58.50 |

65.00 |

4.50 |

6.00 |

|

|

SMTYT6030A-100M |

10.00±20% |

64.00 |

68.00 |

4.50 |

5.50 |

|

|

SMTYT6030A-120M |

12.00±20% |

85.00 |

98.00 |

3.50 |

5.00 |

|

|

SMTYT6030A-150M |

15.00±20% |

98.00 |

115.0 |

3.00 |

4.50 |

|

|

SMTYT6030A-220M |

22.00±20% |

135.0 |

165.0 |

2.30 |

3.10 |

|

|

SMTYT6030A-330M |

33.00±20% |

225.0 |

257.0 |

2.00 |

2.50 |

|

| (1) All test data is referenced to 25℃ ambient . | ||||||

| (2) When applying the heat rating current DC(Idc) to coil, it will cause an approximate △T of 40℃. | ||||||

| (3) When applying the saturation current DC(Isat) to coil, it will cause the initial inductance valuel to drop 30%Typical. | ||||||

| (4) Operating Temperature Range-40℃ to +125℃ | ||||||

4. SMTYT6030A integrated inductor packaging specifications

Packaging Information:

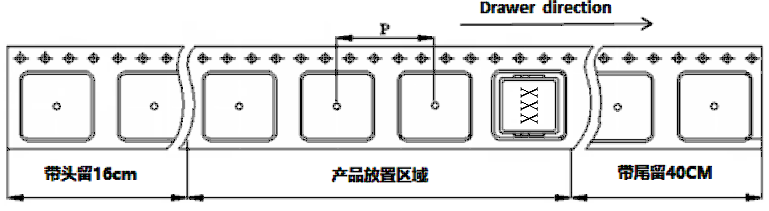

(1)Tape&Reel Dimension

|

A |

B |

C |

W0 |

P |

|

330 |

100 |

13.5 |

16.8 |

12 |

(2)The packing way and quantity

|

|

|

||||||||||

|

Packing quantity per roll: 1500 pcs/Reel |

Quantity per inner box: 4500 pcs/Inner box |

||||||||||

|

|

|

||||||||||

|

Packing quantity per box: 9000 pcs/Carton |

|

||||||||||

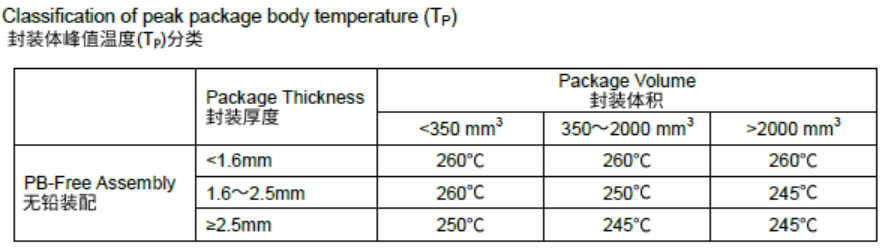

Soldering and Mounting

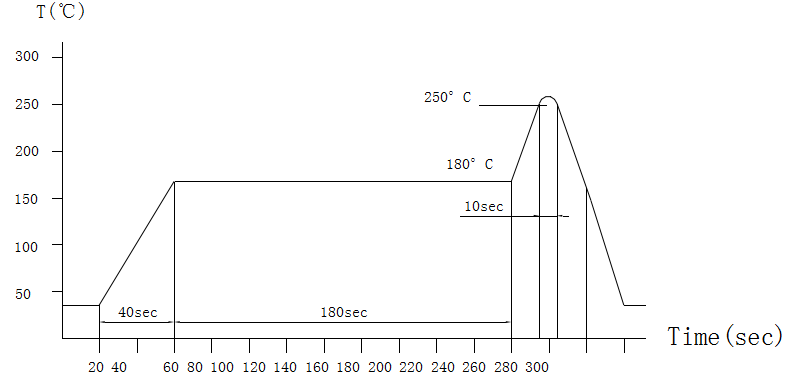

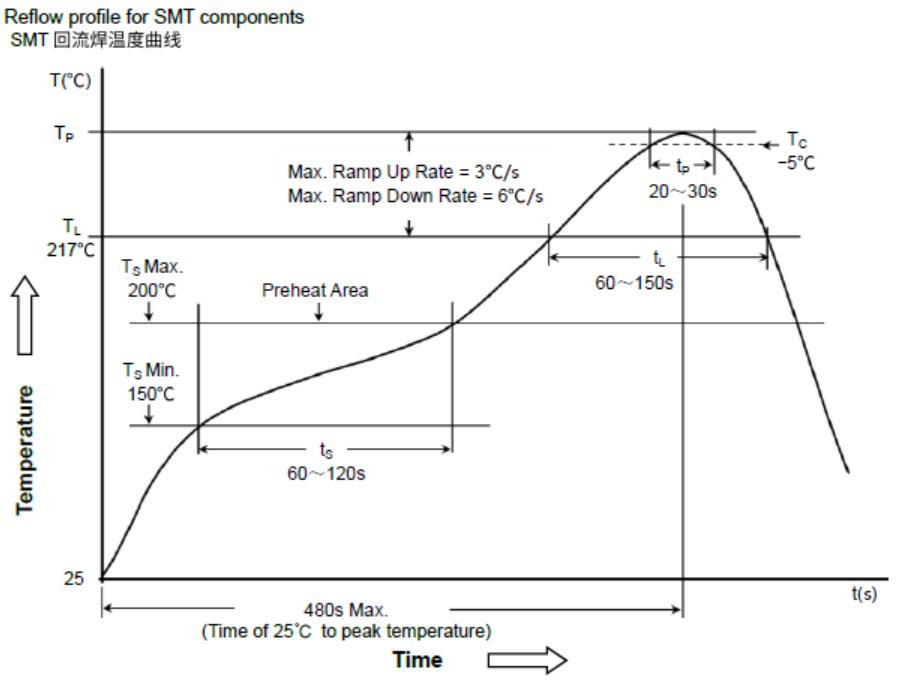

(1). Recommended Reflow Conditions (Lead-free)

The above recommended reflow test conditions are based on the company's reflow welding equipment

(2). Reflow Soldering Heat Endurance

a. Reflow soldering is carried out under this condition and placed under normal temperature and humidity conditions

b.Twice reflow test is acceptable with the test interval remaining 1 hour under the normal conditions.

c.The reflow test profile may vary with the testing instruments.

Reliability Test

|

Item |

Performance |

Test Condition |

||||||||||

|

Solder Ability Test |

More than 90% of terminal electrode should be covered with solder. |

Terminal in flux and then into 245 + 5 ℃ tin furnace 5 seconds |

||||||||||

|

Terminal Strength |

The terminal should not peel off |

After soldering between copper plate and electrode. sample is pushed in three directions of X,Y and Z with force of 5N(0.5kgf ) for 10±5 seconds |

||||||||||

|

Vibration |

1.No separation or indication of electrode. 2.No case deformation or change in appearance. |

Inductance deviation within +10% after vibration for 1 hour. In each of three orientations at Sweep vibration (10~55~10HZ) with 1.5mmP-P amplitudes. |

||||||||||

|

Drop Test |

1.The inductance deviation is within +10%. 2.No case deformation or change in appearance. |

981m/s2 (100G) is used to automatically drop the product at a height of 1 meter after packaging. And there are three different directions |

||||||||||

|

High Temperature Storage Test |

1.No case deformation or change in appearance. 2.△L/L≦10%. 3.△DCR/DCR≦10% |

Temperature:125℃±3℃ Time:500±2 hours. Tested not less than 1 hour, nor more than 2 hours at room |

||||||||||

|

Low Temperature Storage Test |

1.No case deformation or change in appearance. 2.△L/L≦10%. 3.△DCR/DCR≦10% |

Temperature:-40℃±3℃ Time:500±2 hours. Tested not less than 1 hour, nor more than 2 hours at room. |

||||||||||

|

High Temperature Humidity Test |

1.No case deformation or change in appearance. 2.△L/L≦10%. 3.△Q/Q≦30%. 4.△DCR/DCR≦10% |

Temperature:85℃±3℃. Humidity:85±5%RH. Test Time: 500±2 hours. Tested not less than 1 hour. Nor more than 2 hours at room temperature. |

||||||||||

|

Thermal Shock Test Storage Test |

1.No case deformation or change in appearance. 2.△L/L≦10%. 3.△DCR/DCR≦10% |

First–40℃ for 30 Minutes, last 125℃ for 30 Minutes as 1 cycle. Go through 20 cycles. |

||||||||||

5. Product Qualification of SMTYT6030A Integrated Inductor

Production Qualification:

Our production comply the EU standards and reliability test,with high power, low temperature rise and good quality assurance. The quality assurance of integrated inductor is reliable for more than 5 years.

6. Deliver, Shipping And Serving of SMTYT6030A Integrated Inductor

Our SMTYT6030A Integrated Inductor generally have a domestic delivery date of 10 working days; The foreign delivery time is 20 working days. Our packaging adopts three-level packaging, which is firm and reliable, and can effectively protect the products from damage.